LEAD-FREE HOT AIR REFLOW

8 temperature range of the upper and lower environmental protection reflow

soldering, perfect temperature curve, better solder paste curing, high gloss

AOI (AUTOMATIC OPTIC INSPECTION)

AOI automatic optic inspection machine could find out the bad solder joints

quickly and ensure good quality of every piece PCB.

Ultrasonic Welding Machine

The high frequency Signal is converted to high-frequency mechanical vibration, make the interface temperature of the product base and cover reach melting point and combine well. achieve seamless welding and high waterproof level.

Integrating Sphere Test:

Test the performance parameters of LED lights, Such as: fux(Lm),color temperature(wa velength),photosynthetic efciency, etc.

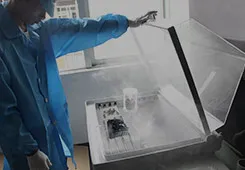

Dust Proof Test

Reference standard: ISO 20653-2013

Dust:Arizona dust 6s movement of the air-dust mixture;

15min break. 20 such cycles be performed.

During the test, the sample was continuously pumped with negative pressure.

Fully Automatic Printer

Fully automated solder paste printing, accurate to 0.02mm,scraping tin evenly.

SMT (Pick And Place)

High speed SMT equipment, fully automated surface mounting and Welding

Cross Cut Test ISO2409-2013

Assessing the resistance of paint coatings to separation from substrates when a right-angle lattice pattern is cut into the coating, penetrating through to thesubstrate.

Waterproof Test

Every light need to pass IP66,IP67,IP68 or IP6K9K waterproof test before delivery. We have two diferent ways to test the waterproof level.

1)Spray on the lamps by high pressure water gun:

2)Test the lamps Under water by 0.03MPa air

negative pressure in the water tank;